Construction of Telarah WPS & Suction Main

Hunter Water Corporation

To cater for future growth in the Maitland/North Rothbury water supply system catchment, Hunter water Corporation staged a series of augmentation works. The contract involves the construction of Telarah 1 Water Pumping Station (WPS) and over 1km associated suction main including but not limited to the following

- Piling of retaining walls. Foundations, thrust blocks

- Diversion of stormwater

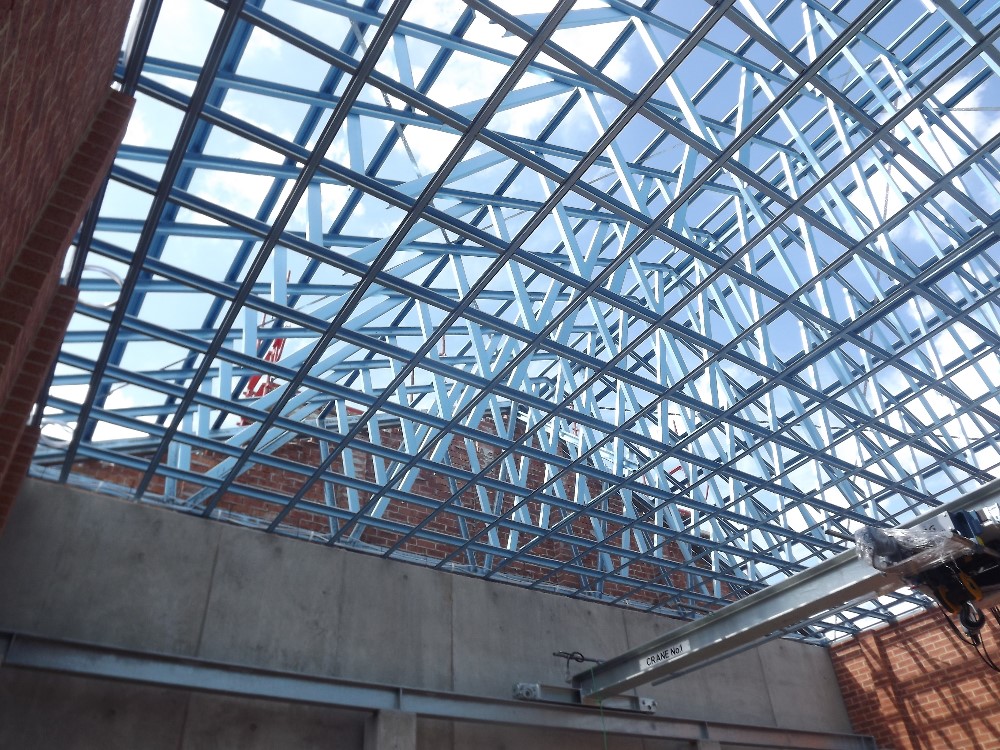

- Construction of Pump station building works. Switch room with sub flooring

- Supply and install Overhead crane & monorail

- Supply and Installation of pumps x 3 in pump station

- Construction of chambers and pits, installation of others

- Supply and installation of all DICL DN 600 pipework. Flange Fittings Valves, Flow meters

- Pressure Transmitter/Gauge Board

- Supply and installation of three variable speed driven pumps

- Air condition, louvres, signage

- Supply and installation switchboards and other electrical equipment

- Supply, installation PLC/Telemetry Hardware

- Supply, installation, programming PLC/Telemetry/Scada Engineering and Software Development

- Supply and installation of substation (kiosk) inclusive of high voltage network upgrade

- Stainless Steel Generator Box Cable Tray & Metering Box

- Supply and installation of substation (kiosk) inclusive of high voltage network upgrade- HV & HV cabling

- Variable Speed Drives

- Building Services (Electrical)

- Earthworks, hardstand, concrete Driveway /Footpaths, fencing and resurface all surfaces, landscaping

- Testing & commissioning

Pipeline

- 1.2km DICL DN600 Plus 250 600mm SCL 6WT suction Main alignment along roadways, adjacent to railway, creeks, light industrial and residential areas. through parkland and over lagoon area including

- 3 trenchless crossings. North Coast Railway, The New England Highway and Bungaree Street

- Open trench road crossing John street

- Install Pipeline off the Pedestrian Crossing over waterway

- Pipe supports, thrust blocks, fittings, and connections

- 2 x Crossover / cut in connections

- Stormwater Crossing

- 300m of 600 stormwater pipe drainage and retaining walls

- Pressure Testing and commissioning

- All other works not specifically stated above

Challenges and achievement

Latent conditions, geotechnical issues which required additional works and impacted on the program of works.

Unknown dependence of trenchless rail crossing on a rail shutdown procession and the requirement of a five days Shut down due to the 100m length of the trenchless crossing, overcoming these issues with pre-boring and use of a 4-day shut down. (dependence on ATRC calendar of a 4-day scheduled shut down) This disrupted the completion of the pipeline as final alignment of the bores were required.

Pipeline route site specific hazards, pedestrian footpath. old Clay pipes, Gas services, Water mains, Wastewater mains, Telstra cabling, Power (overhead and Underground) and stormwater services located along the pipeline route. Alongside &Under railway Corridor, roads and Highways, in residential areas and alongside special needs schools, crossing of waterways and wetlands, Overhead power lines are low in some areas. Working on live systems and commissioning of new electrical assets., Sharing of access to PS site with Manufacturing Factory.

Managing community and stakeholders’ consultation and communication endeavored a smooth project without public complaints.