Wallsend WPS

Hunter Water Corporation

Wallsend WPS is a critical asset in Hunter Water Corporation Water (HWC) distribution system and is responsible for the bulk transfer of water to several districts within Newcastle and over 70,000 people. the upgrade of Wallsend Water Pump Station (WPS) including the following but not limited to;

- Pump station building modifications/installation of new ceiling, painting, non-slip floor, remove windows & doors and install acoustic louvers. Supply and install Fire rating doors and safety equipment

- Extensions to Switch Rooms & new roof, Doors to fire rated standards. Segregation of Switch room Power Supplies

- DEMOLITION: dismantle, dispose of salvage existing pumps & motors pipework and electrical equipment and controls, cables, wiring. transformers and switchboards

- Removal of existing overhead crane and installation of new

- Remove and dispose in environmental and safe manner any asbestos (switchboard) and PCB Polychlorinated Biphenyls) from the pumps

- Construct elevated walkway, handrails, and access ladders

- Verification of design, supply, installation and connection of Flange pipework and valving

- DN450 rising main connections, DN450 pump pipework and stormwater pipework

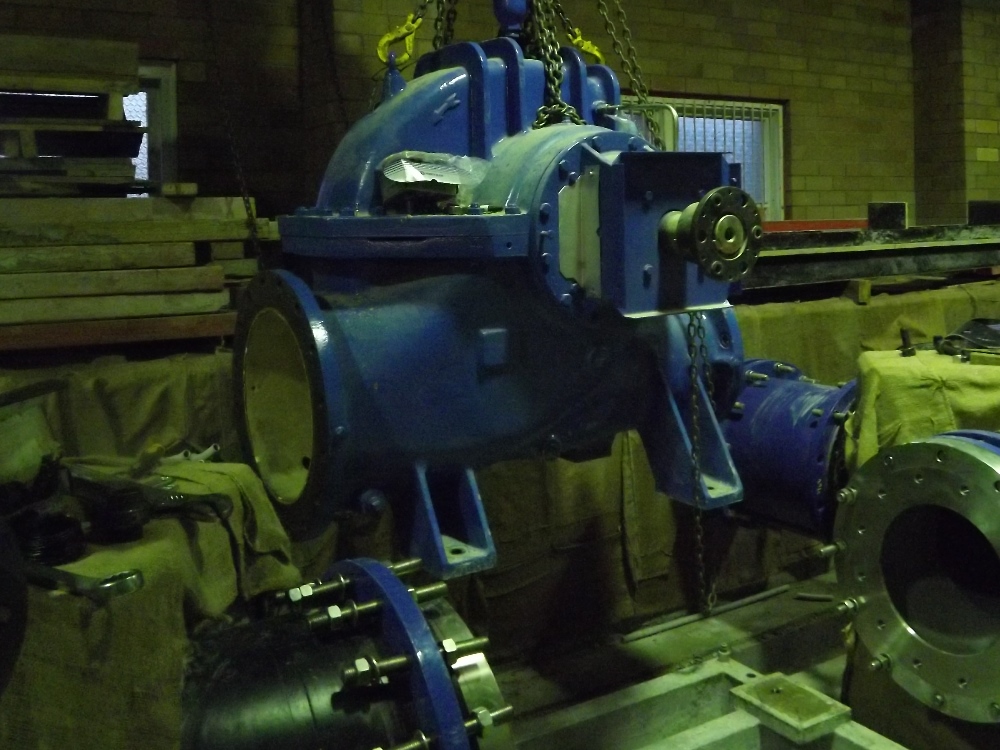

- Upgrade and modify arrangement for six new pumps supply, verification of design pipework. design and install new mild steel pipework fittings, flanging supports. thrust blocks, Header valves & Station Pressure Gauge Board, Pump gauge Boards and other alarms and alert devices

- Supply and install discharge pressure gauges and ball cock fittings on the pipework

- Replace trench drains covers, remove windows & doors, and install acoustic louvers

- Installation, laser alignment, testing and commissioning of six new pumps

- Construction of substations supporting structure and blast walls

- New 11kV poles and associated aerials, earthing and LV mains

- Installation and commissioning of substation,3 Kiosks and connection to Energy Australia 11kV network

- Consumer mains from the new kiosk transformers

- Construct and install three main Switch boards

- Temporary relocation and modification work associated with the electrical installation

- Power and controls for six new pumps & motors including local control panels and field devices

- PLC/SCADA programming including temporary program modifications; required for the conversion, installation and commissioning process

- Generator Connection Facilities, Upgrade to lighting and air conditioner

- Remove and dispose of existing HV switchgear, wiring, cabling, and transformers

- Construct Earthwork, access road construction, retaining walls and stormwater drains and landscaping

- Testing and commissioning

Challenges and achievement

The success was having a diligent team (Civil, mechanical & electrical) and effective, productive communication with the client representative & its network team which allowed a holistic risk management & scheduling planning, and a smooth completion of complex high risk works.

Redesign layout of the switch room to have all switchboards, panels etc. in the same location rather than two separate switch rooms which allowed a smooth transition of the power and pumps to the new systems, easier access, and maintenance for the HWC operational teams.

Completing shutdowns, outages work within the limited time Flames, which avoided disruption to the network and to the Client customers.

Community communication and control of noise results in nil Public complaints.

An Emergency response Plan which allowed mitigation of risks and avoided disruption of services.to the Client customers.

Complex works within a residential Zone and a restricted limited site, Management movement of plant and people, working around & supporting existing infrastructures, Unknown services, transfer of power (HV & LV), electrical and mechanical isolations, Changes to pumping arrangements, Various temporary and Final Scada programs, water under pressure, welding within confined spaces.